Ultra-high power graphite electrode

|

UHP TECHNICAL PARAMETERS |

||||||||||

| (mm)Nominal Diameter | (mm)Nominal Diameter | |||||||||

| Item | Unit | YB/T4090 Industry Standard) | UHP (Measured Value) | |||||||

| 300\400 | 450\500 | 550\600 | 700\800 | 350\400 | 450\500 | 550/650 | 650/700 | |||

| Electric Resistivity | Electrode | μQM | ≤6.2 | ≤6.3 | ≤6.0 | ≤5.8 | 4.5-5.8 | 4.5-5.8 | 4.5-5.6 | 4.5-5.2 |

| Nipple | ≤5.3 | ≤5.3 | ≤4.5 | ≤4.3 | 3.4-3.8 | 3.4-3.8 | 3.4-3.8 | 3.0-3.5 | ||

| Bulk Density | Electrode | g/cm³ | ≥1.67 | ≥1.66 | ≥1.66 | ≤1.68 | 1.73-1.75 | 1.70-1.73 | 1.70-1.72 | 1.70-1.72 |

| Nipple | ≥1.74 | ≥1.75 | ≥1.78 | ≥1.78 | 1.80-1.84 | 1.80-1.84 | 1.83-1.87 | 1.84-1.88 | ||

| Flexural Strength | Electrode | MPa | ≥10.5 | ≥10.5 | ≥10.0 | ≥10.0 | 12.0-14.0 | 12.0-14.0 | 10.0-14.0 | 10.0-14.0 |

| Nipple | ≥20.0 | ≥20.0 | ≥22.0 | ≥23.0 | 22.0-26.0 | 23.0-28.0 | 23.0-30.0 | 25.0-30.0 | ||

| CTE | Electrode | 10℃ | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 | 1.2-1.4 | 1.2-1.4 | 1.2-1.4 | 1.2-1.4 |

| Nipple | ≤1.4 | ≤1.4 | ≤1.3 | ≤1.3 | 1.0-1.2 | 1.0-1.2 | 1.0-1.2 | 1.0-1.2 | ||

| Elastic Modulus | Electrode | GPa | ≤14.0 | ≤14.0 | ≤14.0 | ≤14.0 | 10.0-13.0 | 10.0-13.0 | 9.0-13.0 | 9.0-13.0 |

| Nipple | ≤20.0 | ≤20.0 | ≤22.0 | ≤22.0 | 16.0-18.0 | 16.0-18.0 | 18.0-20.0 | 18.0-20.0 | ||

| Ash | Electrode | % | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | 0.01-0.15 | 0.01-0.15 | 0.01-0.15 | 0.01-0.15 |

| Nipple | ||||||||||

| Nominal Diameter | Cross-Sectional Area | UHP(Enterprise Standard) | |||||||

| YT/t4090(Industry Standard) | (EAF) | (LF) | |||||||

| Permissible Current Load | Current Density | Permissible Current Load |

Current Density | Permissible Current Load |

Current Density | ||||

| in | mm | cm² | A | A/cm² | A | A/cm² | A | A/cm² | |

| 14 | 350 | 937 | 20000-30000 | 20-30 | 21000-32000 | 22-32 | 23000-34000 | 24-35 | |

| 16 | 400 | 1275 | 25000-40000 | 19-30 | 26000-42000 | 20-33 | 28000-46000 | 22-36 | |

| 18 | 450 | 1622 | 32000-45000 | 19-27 | 33000-49000 | 20-30 | 36800-52000 | 23-32 | |

| 20 | 500 | 2000 | 38000-55000 | 18-27 | 40000-60000 | 20-30 | 43000-63000 | 22-32 | |

| 22 | 550 | 2427 | 45000-65000 | 18-27 | 45000-68000 | 18-28 | 45000-69000 | 18-28 | |

| 24 | 600 | 2892 | 50000-45000 | 18-26 | 52000-81000 | 18-28 | — | — | |

| 28 | 700 | 3935 | 70000-91000 | 18-23 | 70000-100000 | 18-27 | — | — | |

| GUIDANCE TO ANALYSIS OF ELECTRODE PROBLEMS | |||||||

| Factors | Body Breakage | Nipple Breakage | Loosening | Tip Spalling | Bolt loss | Oxidation | Consumption |

| Nonconductor In Charge | ◆ | ◆ | |||||

| Heavy Scrap In Charge | ◆ | ◆ | |||||

| Transformer Capacity Too Large | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | |

| Phase Imbalance | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | |

| Phase Rotation | ◆ | ◆ | ◆ | ||||

| Excessive Vibration | ◆ | ||||||

| Clamper Pressure Too High Or Too Low | ◆ | ◆ | ◆ | ||||

| Roof Electrode Socket Disalignment With Electrode | ◆ | ◆ | ◆ | ||||

| Water Sprayed On Electrodes Above Roof | △ | ||||||

| Scrap Preheating | △ | ||||||

| Secondary Voltage Too High | ◆ | ◆ | ◆ | ◆ | |||

| Secondary Current Too High | ◆ | ◆ | ◆ | ◆ | |||

| Power Factor Too Low | ◆ | ◆ | ◆ | ||||

| Oil Consumption Too High | ◆ | ◆ | ◆ | ◆ | |||

| Oxygen Consumption Too High | ◆ | ◆ | ◆ | ◆ | |||

| Long Time Gap From Tapping To Tapping | ◆ | ◆ | ◆ | ||||

| Electrode Dipping | ◆ | ◆ | |||||

| Dirty Joint | |||||||

| Poorly Maintained Lift Plug And Tightening Tool | ◆ | ||||||

| Insufficient Joint Tightening | ◆ | ||||||

| Note:△Indicates Increased Performance.◆ Indicates Decreased Performance. | |||||||

The main raw material for the production of graphite electrodes is petroleum coke. A small amount of asphalt coke can be added to ordinary power graphite electrodes, and the sulfur content of petroleum coke and asphalt coke cannot exceed 0.5%. When producing high-power or ultra-high power graphite electrodes, needle coke is also required. The main raw material for aluminum anode production is petroleum coke, and the sulfur content should not exceed 1.5% to 2%. Petroleum coke and asphalt coke should comply with relevant national quality standards.

Product Specifications

Graphite electrodes are mainly used in ladle furnaces, electric arc furnaces for steelmaking, yellow phosphorus furnaces, industrial silicon furnaces, or copper melting. They are currently the only available products with high levels of conductivity and the ability to maintain extremely high levels of heat in such harsh environments. High quality needle coke in HP&UHP graphite electrodes ensures perfect electrode application. Graphite electrodes are also used to refine steel in ladle furnaces and other smelting processes.

Company Introduction:

my company a professional enterprise that produces and sells graphite products. With over 26 years of experience, we have accumulated overseas clients from over 20 countries. The product is highly praised by customers for its high-quality performance and competitive price. Graphite electrodes are the core product. We have a complete production line, strict quality control system, and diversified transportation solutions to meet the needs of different customers. In addition, we have been committed to continuously improving the quality of our products and services.

The Production Process of Graphite Materials

- Graphite immersed in oil. Before mechanical processing, graphite materials should be immersed in engine oil for dozens of hours to allow oil to penetrate the graphite material, so that the ash powder does not fly during mechanical processing and a smoother surface can be obtained.

- Paint marking. After rough machining of the outer surface of the electrode, a thin layer of white paint is sprayed on the marking surface before marking, so that the lines are clear and convenient for mechanical processing.

- Perform mechanical processing.

Reasons for Choosing Us

Years of industry production experience

The company is a comprehensive graphite supplier engaged in the research and development, processing, manufacturing, and sales of graphite products

Based on strong technological and economic strength, the company continuously develops graphite products with advanced domestic technology levels

We sell conventional graphite electrodes, high-power graphite electrodes, ultra-high power graphite electrodes, and have established cooperative relationships with multiple enterprises.

Frequently Asked Questions

1、When can I get the price?

We usually quote your detailed requirements such as size, quantity, etc. after 1 hourIf it is an urgent order, you can call us directly.

2、Price?

Please send us detailed data on the materials you need when you inquire about our prices

We will give you our most favorable price.

3、Minimum order quantity?

If you place a trial order, we accept 1-100 pieces

4、Do you provide samples?

Yes, samples are available for you to check our quality.

5、What are your delivery terms?

We accept FOB, CFR, CIF, EXW, etc. You can choose the most convenient way. In addition, we can also send products toYou take a plane and express delivery.

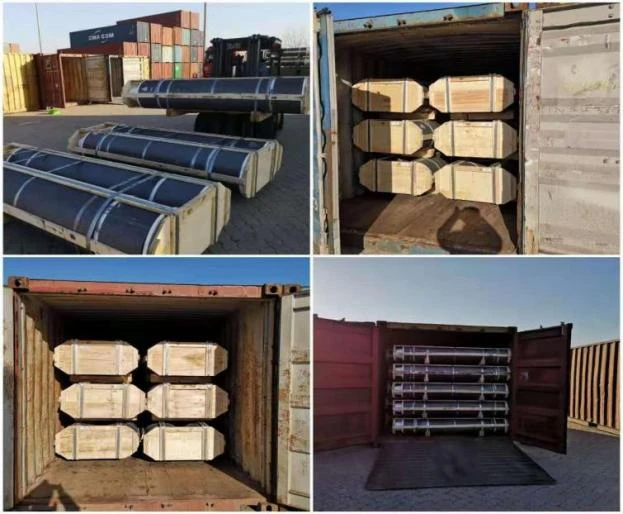

6、Product packaging?

The product will be packaged in bags and boxes, or according to your requirements

7、notice

The actual price will depend on the raw materialsMaterials, exchange rate, and your order quantity.

Delivery Process