Graphite electrodes play a critical role in a variety of industrial applications, particularly in electric arc furnaces (EAFs) for steelmaking, as well as in smelting and refining processes. These electrodes are made from high-purity carbon materials and are prized for their ability to conduct electricity at high temperatures while maintaining structural stability. However, not all graphite electrodes are created equal. They are categorized into different grades, each tailored for specific applications and performance requirements. This article will explore the various grades of graphite electrodes, their properties, and their uses in industrial processes.

Understanding Graphite Electrodes

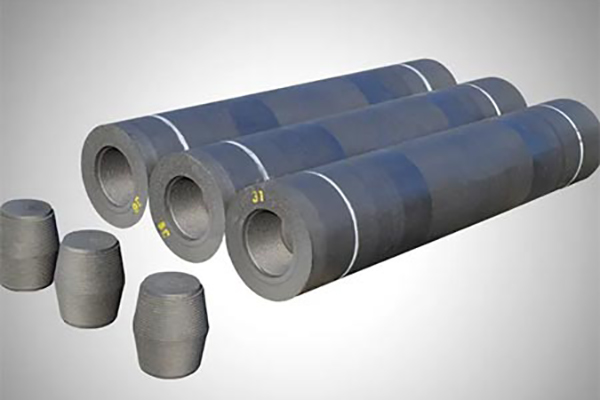

Graphite electrodes are cylindrical rods composed primarily of graphite, a crystalline form of carbon. They are manufactured through a complex process involving calcination, milling, mixing, molding, baking, graphitization, and machining. The final product is a highly conductive and heat-resistant electrode that can withstand the intense heat and electrical currents required in metallurgical operations.

Grades of Graphite Electrodes

The performance of a graphite electrode depends on its grade, which is determined by factors such as raw material quality, manufacturing process, and specific physical and chemical properties. The three primary grades of graphite electrodes are:

- Regular Power (RP) Graphite Electrodes Regular Power (RP) graphite electrodes are the most basic grade and are typically used in applications where electrical resistance and temperature requirements are moderate. These electrodes are designed for low-density electric current and are suitable for use in small to medium-sized electric arc furnaces or ladle furnaces.

- Key Features:

- Moderate current-carrying capacity.

- Suitable for lower power inputs.

- Relatively lower cost compared to higher-grade electrodes.

- Applications:

- Foundries.

- Small-scale steel production.

- Smelting of non-ferrous metals.

- Key Features:

- High Power (HP) Graphite Electrodes High Power (HP) graphite electrodes are an intermediate grade designed for operations requiring higher electrical currents and higher thermal resistance. These electrodes are manufactured using superior raw materials and advanced processing techniques, resulting in a denser and more conductive product compared to RP electrodes.

- Key Features:

- Higher current-carrying capacity than RP electrodes.

- Improved resistance to thermal shock and oxidation.

- Longer service life in demanding conditions.

- Applications:

- Medium-sized electric arc furnaces.

- Steel refining processes.

- Alloy production.

- Key Features:

- Ultra High Power (UHP) Graphite Electrodes Ultra High Power (UHP) graphite electrodes are the highest grade available, engineered for use in ultra-high-performance applications. These electrodes are made from the highest-quality needle coke and undergo rigorous graphitization at extremely high temperatures, resulting in superior conductivity, strength, and thermal resistance.

- Key Features:

- Exceptional current-carrying capacity.

- High resistance to thermal shock and wear.

- Ability to withstand extremely high temperatures and heavy loads.

- Applications:

- Large-scale steelmaking in electric arc furnaces.

- High-performance smelting and refining operations.

- Industrial applications requiring peak efficiency and durability.

- Key Features:

Factors Influencing Grade Selection

The choice of graphite electrode grade depends on several factors, including:

- Furnace Type: Larger electric arc furnaces with higher power demands typically require UHP electrodes, while smaller or less demanding furnaces can utilize RP or HP electrodes.

- Power Supply: The electrical input capacity of the furnace determines the grade of the electrode. UHP electrodes are designed for ultra-high voltage and current, whereas RP electrodes are sufficient for low-power applications.

- Material Processed: The type of material being melted or refined also influences the grade selection. High-performance processes like steelmaking often require UHP electrodes for efficiency and durability.

Advantages of Graphite Electrodes

Regardless of the grade, graphite electrodes offer several advantages that make them indispensable in industrial applications:

- High Electrical Conductivity: Allows efficient transfer of electrical energy to generate heat.

- Thermal Resistance: Can withstand extreme temperatures without melting or degrading.

- Durability: Resistant to thermal shock, oxidation, and mechanical stress.

- Precision: Machinable to precise dimensions, ensuring compatibility with furnace systems.

Challenges and Trends

Graphite electrodes are subject to market fluctuations due to their reliance on needle coke, a key raw material that is also in demand for lithium-ion batteries. This has led to price volatility and increased focus on optimizing electrode performance. Innovations in manufacturing processes and the development of synthetic alternatives aim to address these challenges while maintaining the high standards required for industrial applications.

Conclusion

Graphite electrodes are an essential component in modern industrial processes, particularly in steelmaking and smelting operations. The different grades—Regular Power (RP), High Power (HP), and Ultra High Power (UHP)—offer varying levels of performance tailored to specific applications and furnace requirements. Understanding the characteristics and uses of each grade is crucial for selecting the right electrode for a given process, ensuring efficiency, durability, and cost-effectiveness. As industries continue to demand higher performance and sustainability, advancements in graphite electrode technology will play a pivotal role in meeting these challenges.

Post time: 12-02-2024