Pyrolytic graphite is a unique form of graphite with exceptional properties, making it highly valuable across numerous industries. This article delves into the characteristics, production, and diverse applications of pyrolytic graphite, highlighting why it’s a material of choice for demanding technological environments. We’ll explore its unique structure, thermal and electrical properties, and how these contribute to its use in everything from electronics to aerospace. For professionals like Mark Thompson, understanding these details can offer a competitive edge in the global market.

1. What Exactly is Pyrolytic Graphite?

Pyrolytic graphite is a unique, man-made form of graphite produced through a process called chemical vapor deposition (CVD). Unlike natural graphite or ordinary graphite, pyrolytic graphite is a polycrystalline material, meaning it’s composed of many small graphite crystals. However, these crystals are highly oriented, giving pyrolytic graphite some very special properties. The material similar to graphite is created when a hydrocarbon gas (like methane) is heated to very high temperature in an inert atmosphere. This causes the gas to decompose, and the carbon atoms are deposited layer by layer onto a substrate.

This layered structure is key to understanding pyrolytic graphite. It’s similar to stacking many thin sheets of paper. Each sheet represents a layer of graphene, where carbon atoms are tightly bonded in a hexagonal lattice. These bonds within the plane are very strong (covalent bonds), but the bonds between the graphite layers are much weaker (van der Waals forces). This difference in bond strength between the plane and out of plane, causes the material to have anisotropy.

2. How is Pyrolytic Graphite Made? A Look at the Deposition Process.

The production of pyrolytic graphite involves a sophisticated process known as chemical vapor deposition. Essentially, a hydrocarbon gas, such as methane (CH4), is introduced into a vacuum chamber containing a substrate. The chamber is then heated to extremely high temperature, typically in the range of 2000°C to 3000°C. This intense heat causes the hydrocarbon gas to decompose – a process known as pyrolysis.

During pyrolysis, the carbon atoms from the decomposed gas are deposited onto the substrate. The atoms arrange themselves in a highly ordered, layered structure, forming pyrolytic graphite. The rate of deposition, the temperature, and the pressure inside the chamber are all carefully controlled to influence the final properties of the pyrolytic graphite. Control over these parameters allows for tailoring the material’s density, thermal conductivity, and other characteristics.

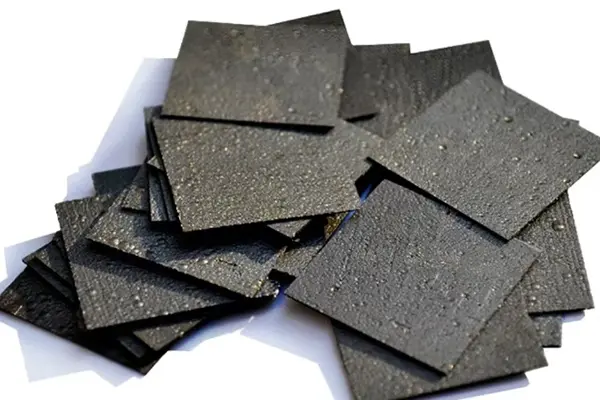

This could potentially include pyrolytic graphite sheets.

3. What are the Key Properties of Pyrolytic Graphite?

The properties of pyrolytic graphite stem directly from its unique, highly oriented layered structure. This creates significant differences in its behavior depending on the direction. Here are some key characteristics:

- Anisotropy: This is perhaps the defining feature of pyrolytic graphite. Its properties are highly directional. Within the plane of the layers (in-plane), it exhibits excellent thermal and electrical conductivity. However, in the direction perpendicular to the layers, these properties are significantly reduced.

- High Thermal Conductivity (In-Plane): Pyrolytic graphite boasts exceptional thermal conductivity along the plane of its layers, even exceeding that of copper at room temperature.

- Low Thermal Conductivity (Perpendicular to Plane): In contrast, its thermal conductivity perpendicular to the layers is very low, making it an excellent thermal insulator in that direction.

- Diamagnetism: Pyrolytic graphite is a strong diamagnetic material, meaning it repels magnetic fields. This property is also anisotropic.

- High Temperature Stability: It can withstand very high temperature in inert atmospheres without significant degradation.

- Chemical Inertness: Pyrolytic graphite is relatively inert, resisting reactions with many chemicals.

4. Why is Pyrolytic Graphite’s Thermal Conductivity So Remarkable?

The exceptional thermal conductivity of pyrolytic graphite in the plane of its layers is due to the efficient movement of phonons (vibrations) through the tightly bonded carbon atom network. Think of it like a wave traveling much faster through a solid, tightly packed material than through a loose, disordered one. The strong covalent bonds within the graphene layers provide a clear pathway for these vibrations to travel with minimal resistance. The thermal conductivity can be up to five times that of copper.

However, because the bonds between the graphite layers are weak (van der Waals forces), phonons have difficulty transferring heat across the layers. This explains the low thermal conductivity in the perpendicular direction. This makes this material suitable for heat sinks.

5. Exploring the Anisotropy of Pyrolytic Graphite.

Anisotropy, as mentioned earlier, is a fundamental characteristic of pyrolytic graphite. It means that the material’s properties are different depending on the direction. This is a direct consequence of its layered structure. A good analogy is wood: it’s much easier to split wood along the grain than across it.

This directional dependence is crucial for many of its applications. For instance, its high in-plane thermal conductivity and low perpendicular thermal conductivity make it ideal for heat spreaders in electronic devices, efficiently drawing heat away from sensitive components while preventing it from spreading to other areas. The ability to cleave the layers of pyrolytic graphite, similar to how mica is cleaved, also stems from this anisotropy.

6. What are the Common Applications of Pyrolytic Graphite?

The unique properties of pyrolytic graphite make it suitable for a wide range of applications, many of which leverage its anisotropic thermal and electrical properties. Some key uses include:

- Heat Spreaders and Heat Sinks: In electronic devices, pyrolytic graphite is used to efficiently dissipate the heat generated by components, preventing overheating and ensuring reliable operation.

- Crucibles and Molds: Its high-temperature resistance and chemical inertness make it a suitable material for crucibles used in high-temperature metallurgical processes.

- Monochromators: Extensively used in x-ray, and neutron monochromators.

- Biomedical Applications: Its biocompatibility has led to its use in certain medical implants.

- Aerospace Components: Its high-temperature stability and lightweight nature make it valuable in aerospace applications.

- Scanning Probe Microscopy: Pyrolytic graphite, especially highly oriented pyrolytic graphite, is used as a substrate for scanning tunneling microscopy (STM) due to its flat, conductive surface. It can be cleaved multiple times.

7. Pyrolytic Graphite in Electronic Devices and Semiconductors.

In the electronic devices and semiconductor industries, pyrolytic graphite plays a crucial role in thermal management. Modern electronics generate significant amounts of heat, and efficient dissipation is critical for performance and longevity. Pyrolytic graphite‘s exceptional in-plane thermal conductivity makes it an excellent material for spreading heat away from hot spots, such as processors and power amplifiers.

Furthermore, its low thermal conductivity perpendicular to the plane helps to isolate heat, preventing it from affecting nearby sensitive components. The thin, lightweight nature of pyrolytic graphite sheets also makes them suitable for use in compact electronic devices where space is limited. The material will also be used in fuel cells for energy storage.

8. How Does Pyrolytic Graphite Compare to Other Forms of Graphite?

While all forms of graphite share the basic hexagonal carbon structure, pyrolytic graphite stands out due to its highly ordered, layered structure. This gives it distinct properties compared to other types, like:

- Natural Graphite: Mined from the earth, natural graphite has a less ordered structure than pyrolytic graphite, resulting in lower thermal and electrical conductivity.

- Ordinary Graphite or Artificial Graphite: This is typically produced from carbon black and a binder, then baked and graphitized. It has a more isotropic structure (properties are similar in all directions) compared to pyrolytic graphite.

- Graphene: While pyrolytic graphite is made up of stacked graphene layers, single-layer graphene has even more exceptional properties. However, producing large, defect-free sheets of graphene remains a challenge.

Comparing these two materials, pyrolytic graphite strikes a balance between performance and manufacturability, making it a practical choice for many applications. Check out the High strength graphite block product page.

9. What are the Limitations and Challenges of Using Pyrolytic Graphite?

Despite its many advantages, pyrolytic graphite does have some limitations:

- Brittleness: It can be relatively brittle and prone to cracking, especially along the cleavage planes.

- Cost: The CVD production process can be expensive, making pyrolytic graphite more costly than some other forms of graphite.

- Machinability: While it can be machined, its anisotropic nature can make it challenging to achieve precise shapes and tolerances. The crystallization and inhomogeneity can effect this.

- Oxidation at High Temperatures: Although stable in inert atmospheres, pyrolytic graphite can oxidize (react with oxygen) at elevated temperatures in air, limiting its use in some high-temperature applications without protective coatings. Should be kept below 400°c.

10. The Future of Pyrolytic Graphite: Emerging Applications and Research.

Research continues to explore new and exciting applications for pyrolytic graphite. Areas of interest include:

- Advanced Thermal Management: As electronic devices continue to shrink and become more powerful, the need for even more efficient heat dissipation solutions will drive further development of pyrolytic graphite-based materials.

- Energy Storage: Its electrical conductivity and layered structure make it a potential candidate for use in advanced batteries and supercapacitors. The material is chemically inert.

- Sensors: Its unique properties are being investigated for use in various types of sensors.

- Biomedical Engineering: Further research into its biocompatibility may lead to new applications in medical devices and implants.

*Studies of molecules Surface scientists use HOPG as a substrate on which to study a variety of aromatic molecules. HOPG provides an exposed clean surface even after remaining in air for hours. The substrate can stabilize the molecules** and provide a conductive plane. - Nanostructure: The nanostructure has been seen to show semiconducting behaviour.

Key Takeaways: Pyrolytic Graphite Essentials

- Pyrolytic graphite is a unique form of graphite with a highly ordered, layered structure.

- It exhibits exceptional anisotropy, with high thermal and electrical conductivity in the plane of the layers and low conductivity perpendicular to the plane.

- It’s produced through chemical vapor deposition (pyrolysis), a process that allows for control over its properties.

- Key applications include heat spreaders, crucibles, aerospace components, and substrates for microscopy.

- It’s a valuable material in electronic devices and semiconductors for thermal management.

- While more expensive than some other forms of graphite, its unique properties justify its use in demanding applications.

- Ongoing research is exploring new applications in energy storage, sensors, and biomedical engineering.

- Remember to explore our High purity 99.9% graphite powder and High temperature resistant graphite crucible for melting product pages.

- Consider us for your electrode material needs.

The graphite’s delocalized π system over the form graphene sheets is responsible for electrical conductivity and thermal stability. - It’s important to understand the delocalized π-bond between the sheets to make informed purchase decisions.

Post time: 03-10-2025