When working with high-temperature applications, insulation, or energy storage systems, you may come across carbon felt and graphite felt. Knowing the difference between these two materials is crucial for choosing the right one for your needs. In this article, we’ll explore what carbon felt and graphite felt are, how they’re made, and where they’re used. By understanding their properties, you’ll be better equipped to make informed decisions for your projects.

What is Carbon Felt?

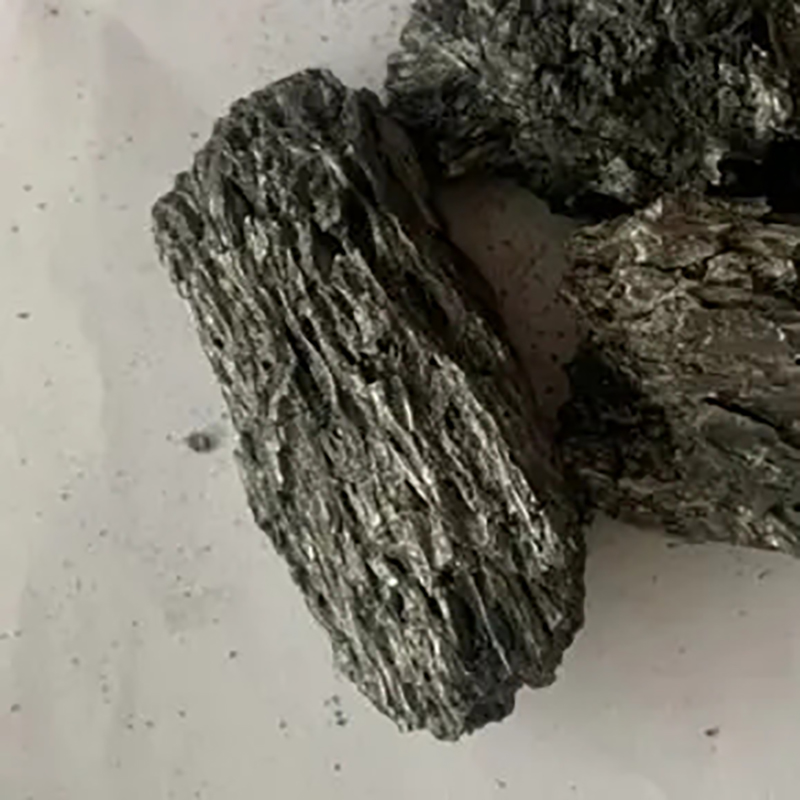

Carbon felt is a soft, flexible material made from carbon fibers. These fibers are often produced from polyacrylonitrile (PAN) or rayon through a process called carbonization. During carbonization, the carbon fiber is heated to temperatures around 1,800°F (1,000°C) in an inert atmosphere, removing non-carbon elements and creating a material with high carbon content.

Properties of Carbon Felt

- High thermal insulation

- Good electrical conductivity

- Lightweight and flexible

- Temperature resistance up to about 1,800°F (1,000°C)

- Porous structure with high surface area

What is Graphite Felt?

Graphite felt is similar to carbon felt but undergoes an additional heat treatment known as graphitization. In this process, the carbon felt is heated to temperatures around 5,000°F (2,800°C) in an oxygen-free environment. This rearranges the carbon atoms into a crystalline graphite structure, enhancing its properties.

Properties of Graphite Felt

- Excellent thermal conductivity

- High electrical conductivity

- Superior chemical stability

- Temperature resistance up to about 5,000°F (2,800°C)

- High purity due to the removal of impurities during graphitization

- Oxidation resistance in non-oxidizing atmospheres

Explore our Ultra-High Power Graphite Electrode for your high-temperature applications.

How Are Carbon Felt and Graphite Felt Made?

Production of Carbon Felt

- Raw Material: Starts with carbon fibers made from PAN-based carbon or rayon.

- Carbonization: Fibers are heated in an inert atmosphere to temperatures around 1,800°F (1,000°C), creating carbon fiber.

- Felt Formation: The carbon fibers are processed into a non-woven felt.

Production of Graphite Felt

- Starting with Carbon Felt: Uses the carbon felt produced from the above process.

- Graphitization: Carbon felt is heated to temperatures around 5,000°F (2,800°C) in an oxygen-free environment.

- Result: The high temperatures cause the carbon atoms to arrange into a graphite structure, forming graphite felt.

What Is the Difference Between Carbon Felt and Graphite Felt?

The main difference between carbon felt and graphite felt is the heat treatment process:

- Carbon Felt: Heat-treated up to 1,800°F (1,000°C). It has a disordered carbon structure.

- Graphite Felt: Heat-treated up to 5,000°F (2,800°C). It has an ordered graphite crystalline structure.

This difference results in:

- Electrical and Thermal Conductivity: Graphite felt has better thermal conductivity and electrical conductivity.

- Temperature Resistance: Graphite felt can withstand higher temperatures.

- Chemical Stability: Graphite felt has higher oxidation resistance and chemical stability.

Applications of Carbon Felt and Graphite Felt

Carbon Felt Applications

- Thermal insulation in furnaces operating up to 1,800°F (1,000°C).

- Electrochemical applications like battery electrodes.

- Chemical processing equipment due to chemical stability.

- Energy storage systems like supercapacitors.

Graphite Felt Applications

- High-temperature insulation up to 5,000°F (2,800°C).

- Electrode materials in flow batteries and fuel cells.

- Applications requiring good thermal and electrical conductivity.

- Used in vacuum furnaces and inert gas furnaces.

Carbon Felt and Graphite Felt Market Overview

The global carbon felt and graphite felt market is growing due to increased demand in various industries:

- Energy Storage: Used in flow batteries, supercapacitors, and fuel cells.

- High-Temperature Insulation: Essential in vacuum furnaces and inert gas furnaces.

- Aerospace and Automotive Industries: Provide thermal protection and insulation.

- Electronics Industry: Used in semiconductor manufacturing processes.

Market Growth Factors

- Rising demand for energy storage solutions.

- Growth in the aerospace sector.

- Advancements in materials with excellent thermal and electrical properties.

- Asia-Pacific region experiencing significant market growth, driven by industries in countries like China.

Rayon-Based vs. PAN-Based Felt: What’s the Difference?

The raw material used to produce carbon felt and graphite felt can be either rayon or polyacrylonitrile (PAN).

Rayon-Based Felt

- Made from rayon fibers.

- Offers lower thermal conductivity.

- Softer texture, known as soft carbon.

- Suitable for thermal insulation where flexibility is needed.

- Used in applications where thermal stability is important.

PAN-Based Felt

- Made from polyacrylonitrile fibers.

- Offers higher mechanical strength.

- Better electrical conductivity.

- Used in applications requiring durability and strength.

- Preferred in industrial sectors.

Pan Graphite vs. Rayon Graphite

The choice between pan graphite and rayon graphite depends on:

- Mechanical Strength: PAN-based graphite felt is stronger.

- Thermal Properties: Rayon-based graphite felt may have different thermal conductivity.

- Application Needs: Choose based on whether you need flexibility or strength.

The Role of Carbon and Graphite Felt in Electrodes

Carbon felt and graphite felt are important in making electrodes for:

- Flow batteries

- Fuel cells

- Supercapacitors

Their porous structure and high electrical conductivity make them ideal for these electrochemical applications.

Looking for high purity graphite products? Check out our High Purity 99.9% Graphite Powder for your applications.

The Importance of Thermal and Chemical Stability

Both carbon felt and graphite felt exhibit excellent thermal stability and chemical stability, making them suitable for use in various industrial sectors. Their ability to maintain properties at high temperatures in non-oxidizing environments is crucial for processes like vacuum furnaces.

Oxidation Resistance and Suitable Environments

Both materials can oxidize in the presence of oxygen at high temperatures. Therefore, they should be used in oxygen-free environments, such as vacuum or inert gas atmospheres, to prevent oxidation and degradation.

Carbonization Temperature of Carbon Fiber

The carbonization temperature of carbon fiber is critical in determining the properties of the resulting carbon felt. During carbonization, the carbon fiber is heated to temperatures around 1,800°F (1,000°C). For graphitization, the temperature of graphite felt can reach 5,000°F (2,800°C), enhancing its properties.

Good Thermal and Electrical Conductivity

Graphite felt offers good thermal and electrical conductivity, making it valuable in thermal applications and as electrodes in energy storage systems. Its high electrical conductivity is essential for efficient energy transfer.

Carbon Fiber Felt is Used in Energy Storage

With the rise of portable electronics and renewable energy, carbon fiber felt is used in energy storage systems like supercapacitors and flow batteries due to its high surface area and porous structure.

Leading Manufacturers and Market Players

Companies like SGL Carbon and Kureha are leading manufacturers in the carbon felt and graphite felt market, providing high-quality materials for various industries. Facilities in locations like Meitingen specialize in producing advanced carbon and graphite materials.

Frequently Asked Questions

What is the Carbon Content of Graphite Felt?

Graphite felt has a carbon content exceeding 99%, making it highly pure and suitable for sensitive applications.

Can Carbon Felt Be Used in High-Temperature Insulation?

Yes, but only up to about 1,800°F (1,000°C). For higher temperatures, graphite felt is recommended due to its superior temperature resistance.

How Does Oxidation Affect Carbon and Graphite Felt?

Both materials can oxidize at high temperatures in the presence of oxygen. They are best used in inert or vacuum environments to prevent oxidation.

What Industries Use Carbon and Graphite Felt?

- Aerospace and Automotive Industries

- Electronics Industry

- Energy Storage Systems

- Chemical Processing

- Industrial Sectors requiring thermal insulation

Where Can I Get High-Quality Graphite Felt?

At Allen’s Graphite Products, we specialize in graphite electrodes and other graphite products. With our high-quality graphite materials and precision machining, we provide solutions for your industrial needs. Please contact us for more information.

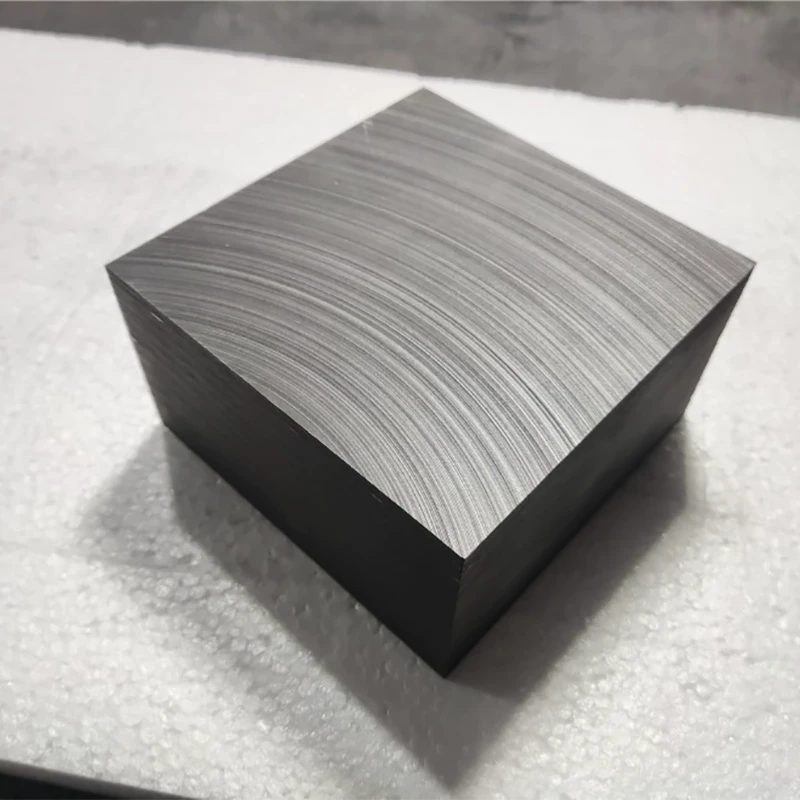

Discover our High Strength Graphite Block for applications requiring durability.

Summary

- Carbon felt and graphite felt are essential materials used in high-temperature and electrical applications.

- Graphite felt is made by heating carbon felt to higher temperatures, resulting in better thermal and electrical conductivity.

- Rayon-based and PAN-based felts offer different properties suited to various applications.

- Understanding the difference between carbon felt and graphite felt helps in selecting the right material for your needs.

- Both materials are used in industries like aerospace, energy storage, and electronics.

- They should be used in oxygen-free environments to prevent oxidation at high temperatures.

- Graphite felt exhibits excellent thermal and chemical stability, making it ideal for high-temperature applications.

- The global carbon felt and graphite felt market is growing due to increased demand in various industrial sectors.

By understanding the properties and applications of carbon felt and graphite felt, you can make informed decisions for your projects. Whether you need high thermal insulation, electrical conductivity, or chemical stability, choosing the right material is key to success.

Post time: 12-17-2024