Graphite blocks are essential materials in various industries, including electronics, manufacturing, and metallurgy, due to their excellent thermal and electrical conductivity, lubricating properties, and resistance to high temperatures. The process of making graphite blocks involves several steps, from sourcing raw materials to final shaping and processing. This article outlines the methods and techniques used in the production of graphite blocks.

1. Sourcing Raw Materials

The primary raw material for graphite block production is petroleum coke, a byproduct of the oil refining process. Other sources can include coal tar pitch and natural graphite. The quality of these raw materials significantly influences the final properties of the graphite blocks, making it essential to select high-quality feedstock.

Petroleum coke is often preferred because it has a high carbon content, typically around 90-99%. In some cases, natural graphite can be used, but it may require additional processing to achieve the desired purity and consistency.

2. Grinding and Mixing

Once the raw materials are sourced, they undergo grinding to achieve a fine powder. This powder is then mixed with a binding agent, commonly coal tar pitch. The binding agent plays a crucial role in holding the graphite particles together during the forming process.

The mixture is thoroughly blended to ensure uniformity, and additives may be included to enhance specific properties, such as strength, thermal resistance, or conductivity.

3. Forming the Graphite Blocks

The next step is forming the graphite blocks, which can be achieved through different methods:

- Compression Molding: The mixed powder is placed in a mold and subjected to high pressure, which compresses the mixture into the desired shape. This method is widely used for producing small to medium-sized graphite blocks.

- Extrusion: For larger blocks or specific shapes, the mixture can be extruded through a die, allowing for continuous production. This technique is beneficial for creating long, uniform blocks.

- Isostatic Pressing: In this method, the mixture is placed in a flexible mold and subjected to uniform pressure from all sides using a fluid medium. Isostatic pressing ensures a denser and more uniform block, which can enhance the material’s mechanical properties.

4. Baking

After forming, the blocks must undergo a baking process, also known as carbonization. This step involves heating the blocks in an inert atmosphere at temperatures typically ranging from 1000°C to 3000°C. The purpose of baking is to remove volatile compounds from the binding agent, transforming it into carbon.

The temperature and duration of this process influence the final properties of the graphite blocks, including their density, strength, and electrical conductivity. Higher temperatures generally lead to better performance characteristics, but they also require more energy and time.

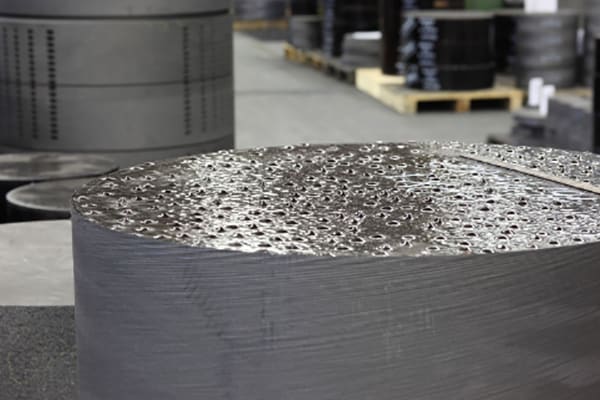

5. Graphitization

To enhance the properties of the baked blocks, a subsequent graphitization process may be performed. This involves heating the blocks to even higher temperatures (around 2500°C to 3000°C) in an inert atmosphere, which converts the carbon structure into graphite.

Graphitization improves the electrical and thermal conductivity of the blocks, making them suitable for various applications in industries such as batteries, electrodes, and heat exchangers.

6. Machining and Finishing

Once the graphitization process is complete, the graphite blocks may require further machining to achieve specific dimensions or surface finishes. This can include cutting, milling, or grinding to meet the specifications required for their intended applications.

Quality control is an essential part of the production process. Testing for parameters such as density, electrical conductivity, and thermal resistance ensures that the final product meets industry standards and customer requirements.

Conclusion

The production of graphite blocks is a complex process that involves sourcing high-quality raw materials, grinding and mixing, forming, baking, graphitization, and finishing. Each step is crucial in determining the final properties of the blocks, which are widely used in various applications due to their unique characteristics. As industries continue to evolve, advancements in graphite block production methods are likely to enhance their performance and broaden their applications, solidifying their role as a vital material in modern technology.

Post time: 09-27-2024