This article delves into the critical role of graphite and carbon in modern industrial applications, focusing on graphite electrodes and carbon anodes. You’ll discover how these anode materials are essential in various sectors, from steel production to energy storage, and why understanding their properties is crucial. As a factory owner and procurement officer, this article will provide key insights to inform your business decisions.

1. What is the significance of carbon and graphite in industrial applications?

Carbon and graphite are indispensable materials in various industrial processes, from steelmaking to energy storage. Their unique properties, including high conductivity, mechanical strength, and resistance to high temperatures, make them suitable for a wide range of applications. Carbon exists in many forms, and each variation offers distinct advantages.

Graphite is a crystalline form of carbon known for its excellent electrical conductivity and lubricating properties. It is a critical component in graphite electrodes, used in electric arc furnaces to melt scrap metal and produce steel. The use of carbon and graphite is fundamental to many industries. The use of graphite is growing, driven by increased demand for graphite electrodes and anode materials.

2. What are anode materials, and why is carbon a prime choice?

An anode is an electrode through which electric current enters a polarized electrical device. In electrolysis and electrochemical cells, the anode is where oxidation occurs. When selecting an anode material, key factors include conductivity, chemical stability, and resistance to corrosion. Carbon stands out as a prime choice due to its versatility and specific properties.

Carbon materials, including graphite, are often preferred for their excellent electrical conductivity, relatively low cost, and availability. Their anode properties are crucial in many industrial processes. The use of carbon as an anode material ensures efficient electron transfer and optimal performance in various applications.

3. What are the different types of carbon used as anode materials?

Various forms of carbon are employed as anode materials, each tailored to specific applications. These include graphite, amorphous carbon, and advanced carbon materials. Each type offers specific characteristics influencing its suitability. The differences in these carbon forms are critical for optimizing the functionality of anode components.

Graphite is widely used due to its high conductivity and thermal stability. Other forms, like carbon black and coke, are often used in composite materials to enhance performance. The variety of carbon sources, including carbon nanotubes, allows for customizing anode properties based on application.

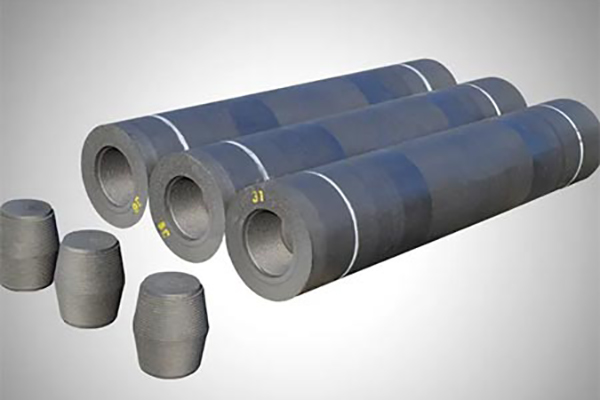

High-power graphite electrode

4. How does graphite’s conductivity make it ideal for electrodes?

Graphite‘s exceptional electrical conductivity makes it an ideal material for electrodes. This property allows graphite electrodes to efficiently conduct high currents, essential for processes like electric arc furnace operation. The electrical conductivity of graphite enables it to deliver the necessary energy for melting metals.

Graphite‘s layered structure and delocalized electrons contribute to its high conductivity. This allows for effective electron transport. This superior conductivity ensures that the electrodes can withstand the intense heat and electrical loads involved in industrial operations.

5. What makes graphite electrodes crucial in electric arc furnaces?

Graphite electrodes are critical components in electric arc furnaces (EAFs). EAFs are used to melt scrap steel and produce new steel. Graphite electrodes are the heart of the EAF process. They conduct electricity to create an arc, generating the high temperatures needed to melt the metal.

The graphite electrodes‘ ability to withstand extreme temperatures, high current density, and corrosive environments makes them indispensable. Their unique properties ensure the efficiency and reliability of the steelmaking process. The success of EAF operations depends significantly on the quality and performance of the graphite electrodes.

6. What are the key properties that define a high-performance carbon anode?

Several key properties define a high-performance carbon anode. Electrical conductivity is paramount, ensuring efficient electron transfer. High mechanical strength is also important. Chemical stability is required to resist corrosion in harsh environments. Surface area and pore structure affect performance in electrochemical applications.

A high-performance carbon anode must also exhibit good cycle life and energy density, especially in energy storage applications. The pore volume and pore structure influence the specific surface of the carbon material. The characteristics of an anode material will directly impact the efficiency and lifespan.

7. How does the anode material impact the electrochemical performance?

The choice of anode material significantly impacts electrochemical performance. For instance, in batteries, the anode material influences factors like energy density, storage capacity, and cycle life. High conductivity and a high surface area promote faster electron transfer.

The electrochemical behavior of the anode is also influenced by its chemical and structural properties. Different carbon materials, such as graphite or carbon nanofibers, can affect the performance of the carbon anode. Improving the electrochemical performance of the anode is a constant objective.

8. What are the applications of carbon and graphite in energy storage?

Carbon and graphite play crucial roles in energy storage technologies, particularly in lithium-ion batteries and supercapacitors. The anode in lithium-ion batteries is typically made of graphite, which provides a stable platform for lithium ion intercalation and deintercalation. Carbon materials offer a combination of properties critical for high-performance batteries.

Graphite‘s layered structure facilitates lithium ion storage, enabling high energy density. In supercapacitors, activated carbon and other carbon materials provide a high surface area for efficient energy storage. Research continues to explore new carbon materials to enhance the energy density and cycle life of energy storage devices.

Conductive graphite rod for electrodes

9. What advancements are being made in graphite anode technology?

The field of graphite anode technology is constantly evolving. Researchers are exploring advanced carbon materials to improve performance. These include graphene anode, carbon nanotubes, and hollow carbon spheres. Each of these carbon-based materials has the potential to revolutionize energy storage.

Efforts focus on enhancing the energy density, cycle life, and storage capacity. Improving the conductivity is another area of innovation. Innovations in carbon material design are continually pushing the boundaries of what’s possible. The drive for better energy storage solutions is propelling advances in graphite anode technology.

10. How do I choose the right graphite or carbon product for my needs?

Choosing the right graphite or carbon product requires careful consideration of several factors. Define your application and its specific performance requirements. Consider the required conductivity, thermal resistance, and mechanical strength. Select the right anode material for your application.

Evaluate factors like cost, availability, and quality control. You will want to carefully assess certifications and supplier reliability. By assessing these factors, you can make an informed decision. Considering these elements will help you select the optimal graphite or carbon product for your needs, whether it’s for graphite electrodes or other industrial applications.

Internal Links:

- High performance pre baked anode carbon block for carbon anode applications.

- Ultra high power graphite electrode specific calcined needle coke block for advanced graphite electrodes.

- High strength graphite tile for applications requiring high mechanical strength.

Key Takeaways:

- Carbon and graphite are essential materials in many industries due to their unique properties.

- Graphite is widely used for electrodes because of its excellent electrical conductivity.

- The quality of the anode material significantly impacts the performance of electrochemical devices.

- Selecting the right carbon or graphite product depends on your application’s specific requirements.

- Continuous advancements are improving the performance of graphite anode technology.

Post time: 02-19-2025