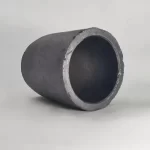

High temperature resistant graphite crucible for melting

| Product Name | Crucible |

| Country of origin | Handan, Hebei |

| Model | N/M |

| High | Customize |

| Material | Graphite |

| Color | Dark Grey |

| Usage | Industry use |

| Package | Wooden box |

| Application | Melt |

| Resistance Temperature | 1500 degrees Celsius |

| Key words | Inclined graphite curling for smelting furnaces |

- The metal melting furnace adopts IGBT power device and unique frequency conversion technology, which operates stably and provides higher reliability and durability.

- Adopting a 100% load design, it can work continuously for 24 hours to improve heating quality. 3. The induction metal melting furnace has a constant current and power control function, greatly optimizing the metal heating process, achieving efficient and fast heating, and fully leveraging the advantages of the product. Under the same conditions, it saves twice the power compared to traditional thyristor intermediate frequency.

- The main power components of the electric induction melting furnace are all German Siemens brands, and the main electronic components are imported products such as Motorola (diode), NEC (transistor), ST (three terminal regulator), FAIRCHILD, ON, etc., which make them work stably and have higher reliability and durability.

- Our company supplies various induction furnaces, with capacities ranging from 1 kilogram ton to 15 tons depending on the type of metal used.

Product Introduction

Graphite crucible, also known as molten copper wrapped in molten copper, is a type of crucible made of graphite, clay, silica, and paraffin as raw materials. Graphite crucibles are mainly used for melting non-ferrous metals, such as copper, brass, gold, silver, zinc, and lead alloys. Graphite crucibles use natural flake graphite as the main raw material, and are mixed with various auxiliary materials such as plastic refractory clay or carbon adhesive. It has the characteristics of high temperature resistance, good thermal conductivity, good corrosion resistance, and long service life. When used at high temperatures, the coefficient of thermal expansion is small, and it has a certain strain resistance quenching and heat resistance. The acid and alkaline resistance to corrosion are strong, and it has excellent chemical stability and does not participate in any chemical reactions during the melting process. The graphite crucible on the inner wall is smooth, and the molten metal liquid is not easily leaked. The crucible on the inner wall has good fluidity and casting performance, Suitable for various molds for casting and forming. Graphite crucibles are widely used for melting alloy tool steels, smelting non-ferrous metals and alloys due to their superior performance

Equipment Features

- The high-density graphite crucible has the best thermal conductivity, and its thermal conductivity is significantly better than other imported crucibles;

- Graphite crucibles have a special glaze layer and compact molding materials, which greatly improve corrosion resistance and extend the service life of the product;

- All graphite components are made of natural graphite in a graphite crucible, which has good thermal conductivity. Graphite crucibles cannot be placed on cold metal surfaces and still have a high specific surface area immediately to avoid rupture and rapid cooling

Company Introduction

- Our company is a professional manufacturer engaged in the research and

development, design, and production of metal melting equipment and related tools.

Our factory has advanced equipment such as large-scale cold isostatic pressing machines, automatic batching and mixing production lines, and specialized crucible sintering machines. The main products are internationally leading level isostatic pressing graphite and silicon carbide crucibles and casting supplies, with an annual production capacity of 4000 tons. Application areas: automotive, electronics, military, aerospace, nuclear waste recycling and disposal, processes required for black metal casting and forging in the marine and railway markets; Precious metal recovery and refining; Cement, glass, ceramics, plastics, rubber, petrochemicals, and pharmaceutical industries.

Metals: copper, steel, aluminum, gold, silver, zinc, lead, precious metals, etc.

Crucible types: circular, elliptical, rectangular, etc.

- Our company is committed to building a large-scale domestic carbon production enterprise, providing a variety of carbon materials and other products. We mainly produce carbon additives (CPC&GPC) and UHP/HP/RP grade graphite electrodes.

Our aim is to take quality as the foundation and customer as the center! At present, our company plans to mainly engage in the production and sales of various particle sizes of calcined petroleum coke and graphite electrode diameters ranging from 75mm to 1272mm. Our professionally screened low sulfur and medium sulfur calcined petroleum coke is mainly used in aluminum pre baked anode materials, casting and refining pot carbonization agents, titanium dioxide production, lithium battery cathode materials, chemical industry, etc,

Our factory has first-class Ban Su production equipment, reliable technology, strict management, and a complete testing system. Our well-established product quality testing laboratory can ensure that every batch of goods meets customer requirements. We have a large logistics team to ensure the safe and timely arrival of each batch of goods at the port. Quality and quantity assurance, as well as high-quality service, are the consistent policies of the enterprise.

We sincerely hope to work with friends from all over the world to build our enterprise into a more dynamic, challenging, and thriving group enterprise with the best products, services, and reputation.