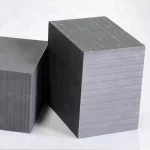

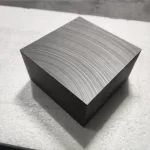

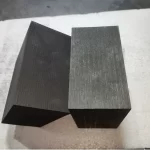

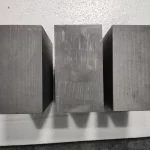

High strength graphite block

| Product Name | Graphite Block |

| Place of Origin | Handan, Hebei |

| Type | Refractory |

| Color | Black |

| Applicattion | Industrial |

| Materials | Graphite |

| Key Word | Graphite Block |

| Feature | Extrusion Resistance |

| Size | Custom Size |

| Diameter | Requirements |

Product Introduction

Graphite electrodes are made of high-quality low ash materials, such as petroleum coke, needle coke, and coal tar pitch. After calcination, packaging, kneading, shaping, baking and pressure impregnation, graphitization, and then precision machining with professional CNC machining. These products have the characteristics of low electrical resistivity, good conductivity, low ash content, compact structure, good oxidation resistance, and high mechanical strength, and are widely used in LF, arc furnace, steelmaking, non-ferrous metals, silicon and phosphorus industries. Therefore, it is the best conductive material for electric arc furnaces and melting furnaces. The characteristics of graphite electrodes: Our graphite electrodes have low resistance, high density, high oxidation resistance, precise processing accuracy, especially low sulfur and low ash content, which will not give steel a second time.

- Low resistance

- High density

- Good conductivity

- High antioxidant capacity

- Precision machining accuracy

- Low sulfur and low ash content, no secondary impurities in the steel

As one of the most important graphite products, graphite blocks are widely used in metallurgy, machinery

Electronics and chemical industries, etc. It is formed by vibration or extrusion, isostatic.ca, and graphitization under precise technical control.

Application:

- Mold: Hot press mold, static casting mold, centrifugal casting mold, pressure casting mold, and melt refractory mold.

- Furnace components: resistance heating element, induction base, structural element, and loading plate,

Used for pulling furnace linings, insulation covers, and covers for monocrystalline silicon or optical fibers.

- Anodes for electrolyzing metals.

- Cathode in aluminum electrolysis cell.

- Parts of heat exchanger.

- A crucible for melting and reducing.

- Ships and pallets used for sintering.

- Magnesium electrolysis and nickel electrolysis.

Company Advantages

1.Factory price without intermediary costs.

2.Our technical engineers have 20 years of experience in the graphite industry

3.To save costs for customers, professional technicians recommend supporting materials based on the working conditions provided by customers

4.Graphite specific CNC equipment, our equipment has professional graphite dust protection, ensuring the accuracy and stability of the equipment during the processing, ensuring strict product quality, and timely order delivery.

5.After sales service is guaranteed, with a dedicated after-sales service team to solve problems for customers

Our quality control department is mainly responsible for raw material inspection, sampling inspection, and final quality control. Every task done by the quality control department is to ensure the provision of high-quality products to our customers.

This is an experienced and innovative sales team, each with over 10 years of experience in foreign trade sales. They can quickly respond and provide appropriate advice, offering competitive prices and high-quality products to customers in different industries.

Diversified product packaging:

Diversified product packaging provides customers with specific packaging based on product characteristics to ensure normal use after receipt. Packaging: The inner packaging is double protected with vacuum and buffered bubble bags, while the outer packaging is double insured with a five layer corrugated cardboard box and a sturdy and durable wooden box, providing absolute protection for product transportation and offering customers a reasonable low-cost transportation plan.

Company Profile

We provide a wide range of qualified graphite products, widely used in industries such as diamond tools, smelting, and refractory materials. We are located in Handan City, Hebei Province, China. It covers an area of 50 square meters. We currently have over 200 employees and mainly produce molded graphite and isostatic pressing graphite. Committed to strict quality control and thoughtful customer service, our experienced employees are always available to discuss your requirements and ensure complete customer satisfaction. The product sells well in various provinces and cities across the country, and is also exported to customers in Europe and the United States. If you are interested in any of our products or would like to discuss custom orders, please feel free to contact us at any time. We look forward to successfully establishing business relationships with new customers around the world in the near future!

Series

- Quality assurance, we use high-end raw materials and conduct strict inspections throughout the entire process.

- Provide professional design solutions, on-site technical assistance, and any other consulting.

- Price advantage, directly provided by the manufacturer, saving a lot of intermediate costs.

- Professional team, specializing in the production of refractory materials for 2000 years

- High production capacity and fast delivery.

6.24 * 7 online service.