Extra Large Graphite Electrode

| Product Name |

Extra Large Graphite Electrode |

| Origin | Handan, Hebei |

| Model | RP, HD,HP,SHP,UHP |

| Type | Graphite electrode block |

| Application | Steel Making |

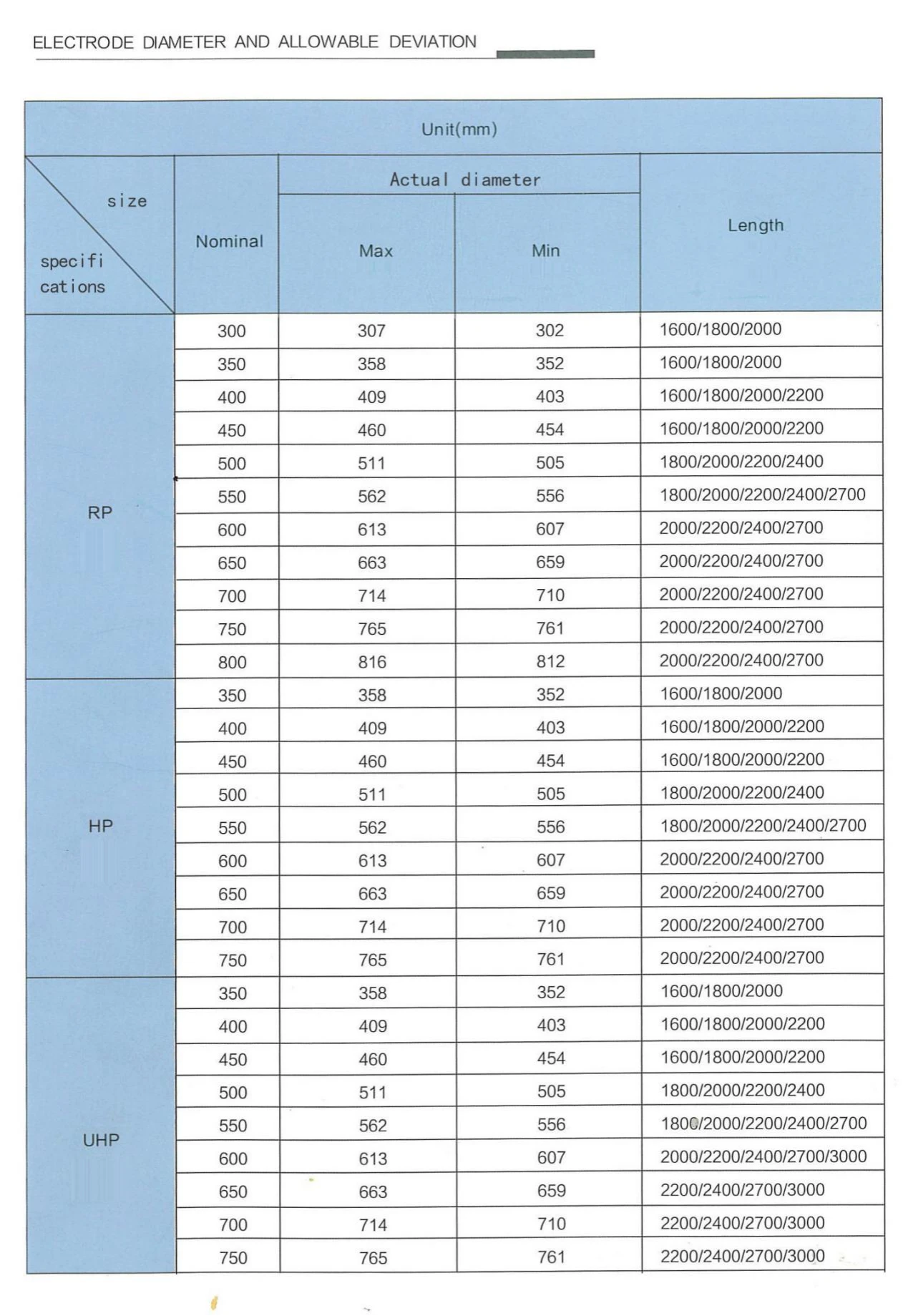

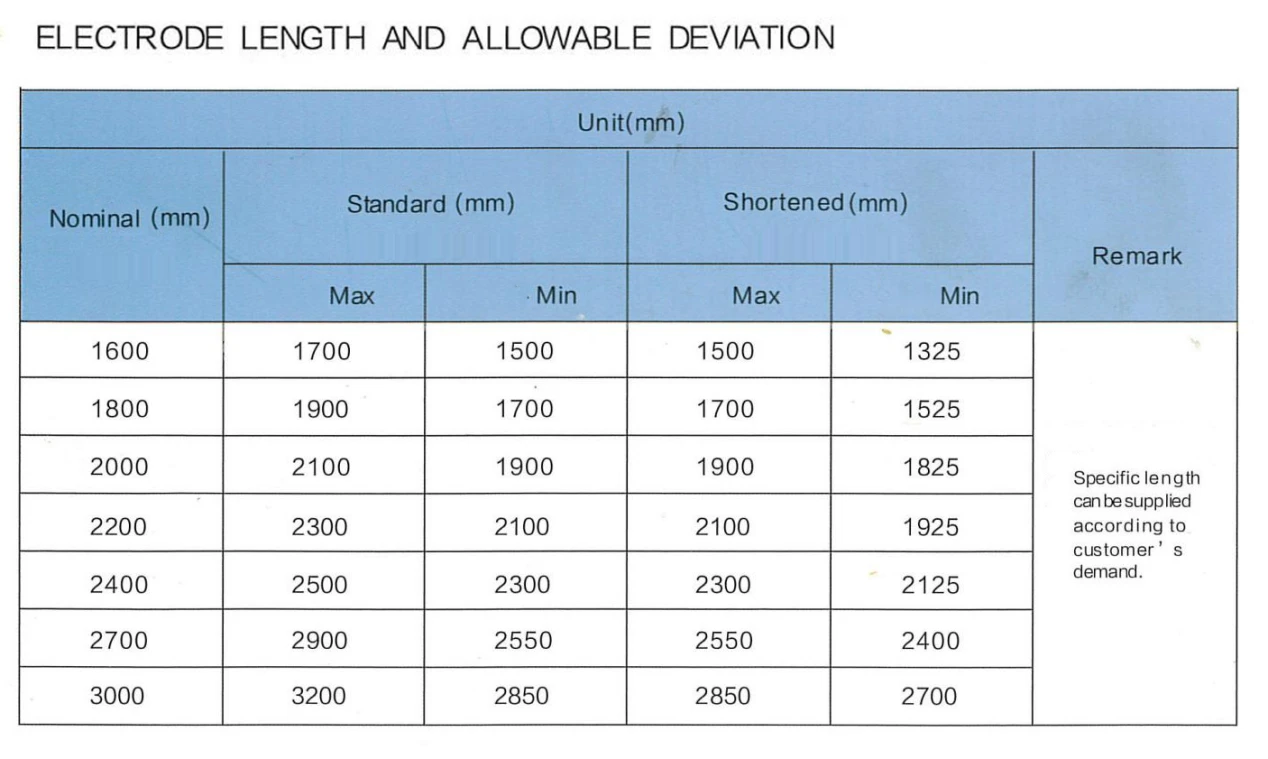

| Length | 1600~3000mm |

| Grade | Maximum battery capacity |

| Coefficient of thermal expansion | 1.5 - 2.8 X10-6 / (100-600 ) |

| Nipple | 3TPI/4TPI/4TPIL |

| Superiority | Low Consumption Rate |

| Flexural Strength (N/㎡) | 8-12 Mpa |

| Thermal Expansion | 1.5 - 2.8 X10-6 / (100-600 ) |

| Apparent Density | 1.58 - 1.76 G/cc |

Graphite electrode refers to a high-temperature resistant graphite conductive material made from petroleum coke and asphalt coke as aggregates, coal tar pitch as binder, through raw material calcination, crushing and grinding, batching, kneading, shaping, calcination, impregnation, graphitization, and mechanical processing. It is called artificial graphite electrode, which is different from natural graphite electrodes prepared from natural graphite.

Brief Introduction

Graphite electrode is a high-temperature resistant graphite conductive material produced through a series of processes, including mixing, shaping, calcination, impregnation, graphitization, and mechanical processing, using petroleum coke and needle coke as aggregates and coal tar pitch as binder. Graphite electrodes are important high-temperature conductive materials for electric furnace steelmaking. Electric energy is input into the furnace through graphite electrodes, and the high temperature generated by the arc between the electrode end and the furnace material is used as a heat source to melt the furnace material for steelmaking. Some other smelting furnaces for materials such as yellow phosphorus, industrial silicon, and abrasives also use graphite electrodes as conductive materials. Utilizing the excellent and special physical and chemical properties of graphite electrodes, they have also been widely used in other industrial sectors.

Advantages of Graphite Electrode

- 1.The process of graphite electrode production is simple, high efficiency, small graphite loss

- 2.Fast processing speed, lower production costs

- 3. Different sizes available, including large diameter

- 4. Our graphite electrodes are very durable and have a long service life5,Our graphite electrodes are with low electric resistance, high density, high anti-oxidation capability, precise machining accuracy, especially with low sulphur and low ash will not give steel second time

The Processing Form of Graphite Materials

-

- Pressure vibration method:

The pressure vibration method requires a specialized machine tool, and the electrode mother mold is opposite in shape to the electrode. Graphite materials and forming tools are placed relative to each other during processing, leaving a certain gap. Inject a processing fluid made by mixing water and abrasive into it. Simultaneously, ultrasonic vibration is generated on graphite and forming tools through the processing fluid. Under the action of abrasive impact, graphite is stripped off in small amounts to form the desired shape. The abrasive is SiC, B4C or diamond, and the coarser the abrasive, the faster the processing speed. The machine tool is processed using sealed and water curtain methods during operation. Electrical discharge machining suitable for mass production situations.

- CNC automatic forming method:

The CNC automatic forming method requires a dedicated graphite electrode forming machine, which adopts CNC mode and has a tool automatic switching device, which can accommodate multiple tools. To improve the processing environment, the graphite electrodes are surrounded by a water curtain to prevent the dispersion of graphite dust. In addition, wet machining method can also be used, which uses water-soluble cutting fluid to prevent tool wear and graphite dust dispersion. The machine tool has a high-performance filtering device that can separate cutting fluid and graphite chips, ensuring long-term continuous processing. It is an ideal specialized equipment for graphite electrode processing, suitable for electrode processing in molds. However, its price is relatively high and its application in China is not yet widespread.

- Mechanical processing method:

Mechanical processing method is the main method used by general mold production units in China.

Graphite Electrode Application

1 for EAF arc furnace;

2 for ore-thermal furnace; for the resistance furnace;

3 for the production of profiled graphite products;

4 for the production of shaped graphite products. Diameter of electrodes: from 75 to 800mm.

We can produce various specifications in accordance with customer requirements. Our advantages: Manufacturer from China; Buy directly from the factory; High-quality products; Profitable price.

Company Introduction

Our company was established in the late 1990s. Through continuous innovation and development, it has become a professional enterprise in the production and sales of graphite products.With more than 26 years of experience, we have accumulated overseas customers from more than 20 countries.This product has been highly praised by customers for its high-quality performance and competitive price.Graphite electrodes are the core product.We have complete production lines, strict quality control systems and diversified transportation solutions to meet the needs of different customers.In addition, we have been committed to continuously improving the quality of our products and services.

Our main products include graphite electrodes, graphite rods, graphite blocks, etc.