Customized high carbon calcined smokeless coal

Product Introduction

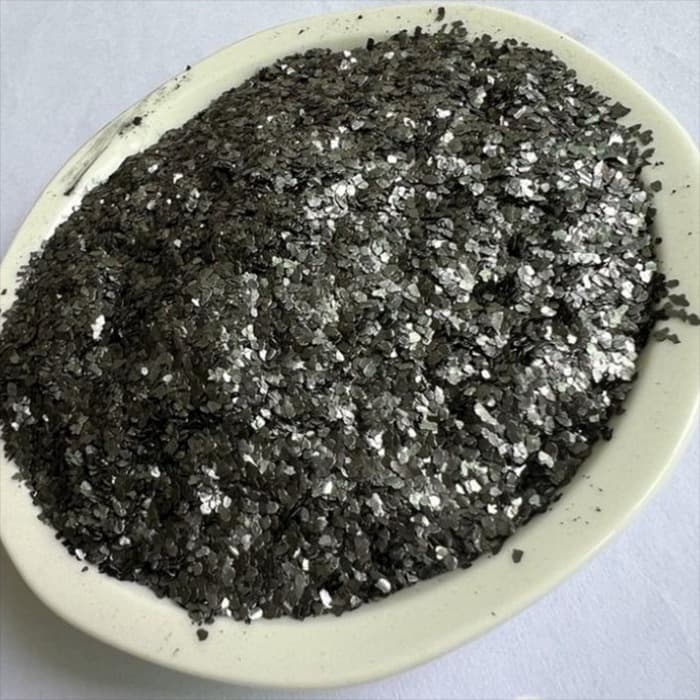

Calcined smokeless coal "is also known as" gas calcined smokeless coal ". Its main raw material is unique high-quality anthracite, which has the characteristics of high fixed carbon content, strong oxidation resistance, low ash content, low sulfur and phosphorus content, high mechanical strength, high chemical activity, high coal purity, and high recovery rate. Carbonizers are mainly used as fuel and additives. As a carbon additive for steelmaking and casting, they can fix more than 95% of carbon.

High-carbon calcined smokeless coal is smokeless coal that has undergone high-temperature calcination treatment.

Anthracite itself has the characteristics of high fixed carbon content, low volatile matter, and low sulfur content. After calcination treatment, its carbon content is further increased, while the volatile matter and moisture content are reduced, improving the chemical stability, conductivity, and thermal stability of anthracite.

High-carbon calcined anthracite has the following advantages:

- Higher calorific value: can provide more efficient energy output.

- Lower impurity content: reduces the pollutants generated during the combustion process.

- Good conductivity: Suitable for some industrial fields that require conductive materials.

It has a wide range of applications in the following fields:

- Metallurgical industry: used as a reducing agent in the production of ferroalloys, calcium carbide, etc.

- Chemical industry: used for manufacturing chemical products such as synthetic ammonia and fertilizers.

- Refractory materials: used as raw materials for manufacturing refractory bricks, etc.

When choosing high-carbon calcined anthracite, attention is usually paid to its fixed carbon content, volatile matter, ash content, sulfur content, particle size and other parameters to meet different usage needs.

High-carbon calcined anthracite is an additive used to increase the carbon content in metal materials such as steel and cast iron.

Its main functions include:

- Adjust the carbon content of the